|

收藏

商品说明

产品概述 Product Description CG系列重型卧式车床为我公司根据长期生产卧车的经验,采用国际上先进的设计手段和制造技术,执行国家现行最新精度标准,精心设计的一种集电气、自动控制、液压控制和现代机械设计等多学科、多门类的精密制造技术为一体的机电一体化机床产品。机床结构性能适用,机床具有动静态刚度高、使用寿命长、加工效率高、各项功能安全可靠、操作方便和造型美观等特点。 1、CG系列重型卧式车床适用于高速钢、硬质合金钢等刀具,对黑色金属、有色金属和部分非金属的轴类、圆筒类和盘类零件,进行车削外圆、端面、切槽、切断、镗孔等 2、CG系列重型卧式车床主传动与进给传动采用分离式结构。 3、CG系列重型卧式车床床身采用整体三导轨,床身导轨采用磨削加工或镶钢结构的低磨擦副滑动平导轨。 4、CG系列重型卧式车床的主传动由直流电机驱动,经机械三档变速,实现主轴的转速范围。 5、主轴箱主轴为穿轴式结构,采用高精度可调径向间隙的双列短圆柱滚子轴承,经优化设计采用较大的主轴直径及最佳支承跨距,提高了主轴的回转精度和动、静刚度。主轴上的顶尖采用法兰式短锥柄结构,提高了顶尖与主轴的连接刚度。 6、刀架横向采用梯形丝杠或滚珠丝杠,纵向采用高精度齿条及双齿棒消隙结构,提高了刀架的传动精度。 7、尾座为整体箱形结构,套筒内的芯轴采用高精度可调径向间隙的双列短圆柱滚筒内的芯轴采用高精度可调径向间隙的双列短圆柱滚子轴承,顶尖为法兰式短锥柄顶尖,使尾座具有很高的刚度,套筒和尾座均为机动,并装有液压测力装置。 8、可根据用户要求,提供双刀架、铣镗装置、磨削装置、冷却液装置等。 CG series heavy duty horizontal lathe is an electromechanical machine tool integrating electrical control, hydraulic control, modern machinery design and other disciplines, Our heavy duty horizontal lathe executes national lastest accuracy standard, which is designed and manufactured according to the international advanced technology and our many years experience. This kind of horizonta lathe has a perfect structure performance with high rigidity, longer service life, higher efficiency, safe and stable function with easy operation. 2.Main transmission and feed transmission of CG series heavy duty horizontal lathe adopts separate structures. 5.The main shaft of headstock is a cross-axle structure, which adopts double-row short cylindrical roller bearing with high precision and adjustable radial clearance. and adopts a larger spindle diameter and the best supporting span through optimization design, which improves the rotary accuracy and dynamic and static stiffness of the spindle.The center on the spindle adopts the flange type short taper shank structure, which improves the connection rigidity between the center and the spindle. 7.The tailstock is a kind of intergal box structure, the inner shaft adopts double-row short cylindrical roller bearing with high precision and adjustable radial clearance, and the center is a kind of flange type short taper shank, so that the tailstock has high rigidity. The sleeve and tailstock are both automatic and driven by the motor and equipped with hydraulic force measuring device. 8.This kind of heavy duty horizontal lathe can be also installed double cutting tool carriages, milling & boring device, and cooling device. 产品实拍 Product Pictures

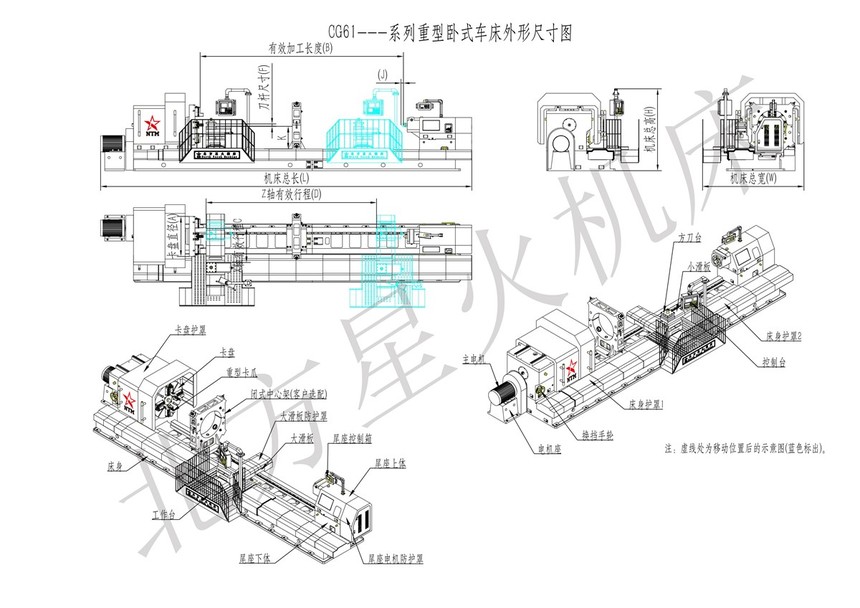

产品尺寸 Product Dimensions

产品参数 Datas

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||