|

机械落地车床

收藏

商品说明

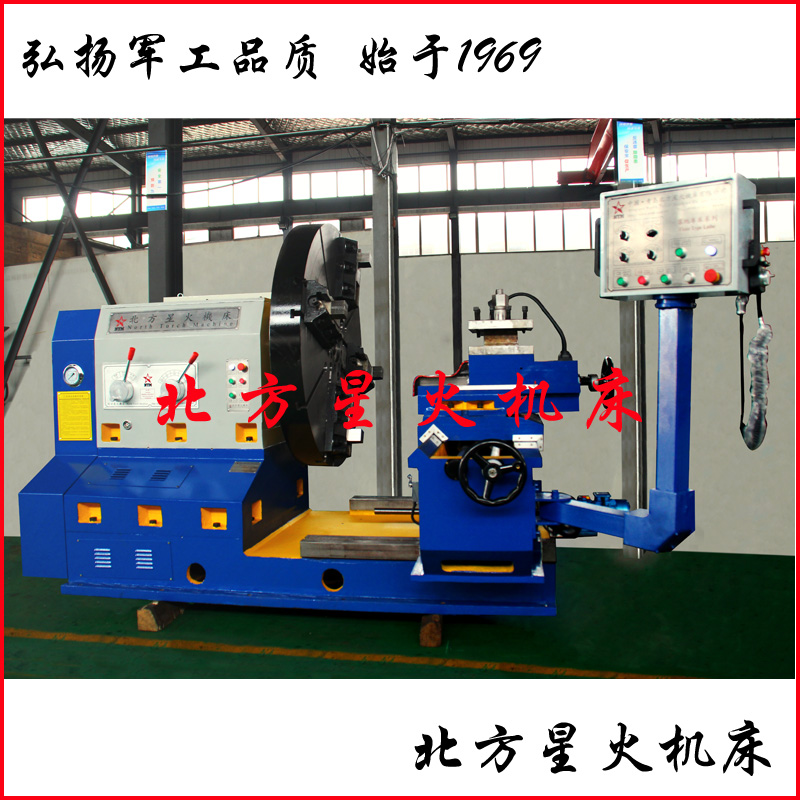

产品概述 Product Description 落地车床,又称大头车床、花盘车床、地坑车床。底座导轨采用矩形结构,跨距大、刚性好、适宜于低速重载切削。操纵站安装在前床腿位置,操作方便,外观协调。落地车床结构采用床头箱主轴垂直于托板运动的床身导轨,床头箱和横向床身连接在同一底座上,底座上为山型导轨结构,可手动调节托板的横向移动。机床铸件通过振动时效消除内应力,床身也经过超音频淬火,导轨磨加工。本机床承载能力大,刚性强、外形美观、操作方便、能够车削各种零件的内外圆柱面、端面、圆弧等成型表面,是加工各种轮,胎模具及大平面盘类,环类零件理想设备。落地车床主要用于车削直径较大的重型机械零件,如轮胎模具、大直径法兰管板、汽轮机配件、封头等,广泛应用于石油化工、重型机械、汽车制造、矿山铁路设备及航空部件的加工制造。 Floor Type Lathe is also named as Large Head Lathe, Disc Lathe and Pit Lathe. The base guide rail adopts rectangle structure with big span, high rigidity and suitable for heavy turning with low speed. The operation station is installed on the front positions of machine with convenient operation and coordinate appearance. The structure of floor type lathe adopts the machine bed guide with the headstock spindle perpendicular to the support plate. The headstock and horizontal machine bed are the complete part and connected on the same machine base. The machine base is a kind of mountain guide structure, the horiozntal movement can be adjusted manually. The internal stess of machine castings can be eliminated by vibrating movement. The machine bed is also quenching by the super-audio and guide rail is grinding also. This machine has a large bearing capacity, strong rigidity, beautiful appearance and easy operation, which can machining various parts of the inside and outside cylindrical surface, end face, arc and other formed surface,it is the ideal equipment for processing various wheels, tires and large plane plate type, ring type parts. Floor type lathe is mainly used for turning large diameter heavy machinery parts, such as tire mold, large diameter flange tube plate, steam turbine parts, sealing head, widely used in petrochemical industry, heavy machinery, automobile manufacturing, mining and railway equipment and aviation parts processing and manufacturing. 产品实拍 Product Pictures

产品尺寸 Product Dimensions

|